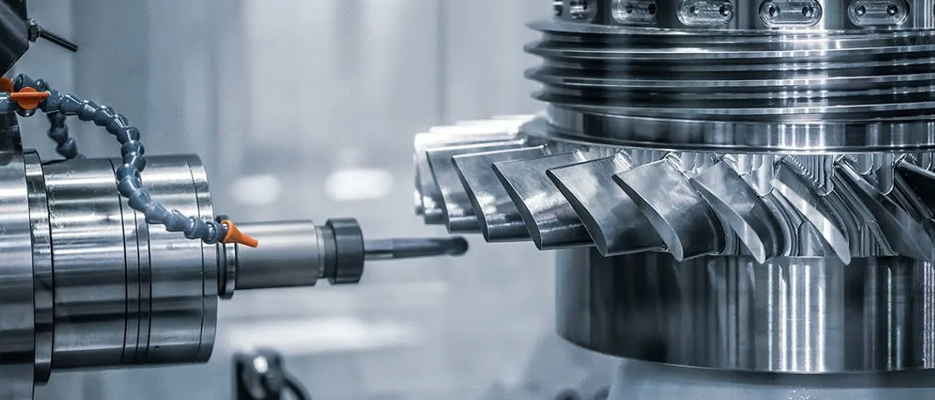

How to Select the Right Helical Gearmotor for Your Application

Choosing the right Helical Gearmotor is critical to ensuring equipment longevity, energy efficiency, and optimal performance. Here's a step-by-step guide to help you make the best choice for your industrial setup.

1. Define Load and Torque Requirements

Calculate the output torque needed for your application. MES-Drive Gearbox offers a wide range of high-torque helical geared motors to meet demanding workloads.

2. Select the Proper Gear Ratio

The gear ratio determines the output speed and torque. Lower ratios offer higher speeds with lower torque, while higher ratios provide greater torque at slower speeds.

3. Check Mounting and Shaft Options

Depending on your design, you may need a foot-mounted, flange-mounted, or shaft-mounted configuration. MES-Drive’s modular designs fit easily into your system.

4. Consider Environmental Factors

For dusty, humid, or high-temperature environments, choose gearmotors with proper IP ratings and protective coatings.

5. Choose Energy Efficiency

Helical gearmotors are known for their energy efficiency. MES-Drive helps reduce power loss while delivering consistent output over long periods.

Need Help Choosing?

Contact MES-Drive’s technical team for support in selecting and customizing your next industrial helical geared motor.

Leave A Reply

Your email address will not be published. Required fiels are marked